We offer complete or partial machine repair/rebuilding. Our unique approach allows our customers to select the scope of the project to fit their needs and budget, from a simple repair to a full ’top-to-bottom’ restoration.

At Reg-Ellen, one of our main goals is to meet or exceed our customer’s expectations - this is especially important during the machine rebuilding process. Rather than offering a vague description of the work to be completed with a bottom-line dollar amount, we perform a detailed machine teardown and inspection. By providing you with a thorough machine inspection report, we can enable you to precisely determine the scope of work.

The Reg-Ellen Approach to Machine Rebuilding

-

Step 1: Shipment, disassembly and inspection. The customer ships the entire machine to our facility, where we can strip the machine down, clean it, and inspect it to determine if it is a candidate for rebuilding. In the past, we have uncovered damage to machine internals that was not evident from the outside. It is far better to know ahead of time if a rebuild or repair is economically viable before the project begins. As we inspect the machine, we take hundreds of measurements to determine the level of wear on each assembly. Here is a sample of an inspection worksheet for a Waterbury Threader Slide Assembly.

-

Step 2: Quotation by assembly. After inspection, we generate a statement of condition to provide to the customer. We break down the machine by assembly, using the OEM manual as our guide, and provide our recommendations for the scope of work required. This includes a detailed list of parts and procedures that would have to be accomplished to bring the machine up to the level required. A complete machine re-manufacture would require every working part to be replaced with a standard OEM part, manufactured to original specifications. A more economical approach would be to reuse parts (when possible) and to use oversize parts where required. The choice is entirely up to the customer, and can be tailored to their requirements.

-

Step 3: Scope of project determination. The customer, after reviewing the provided statement of condition and associated quotations, can now select which options are required to meet their budget and time requirements. We then prepare a formal order, and establish a timeframe for the repair process. This method allows the customer to control both the costs and the scope of the rebuilding process, and helps us meet their expectations.

-

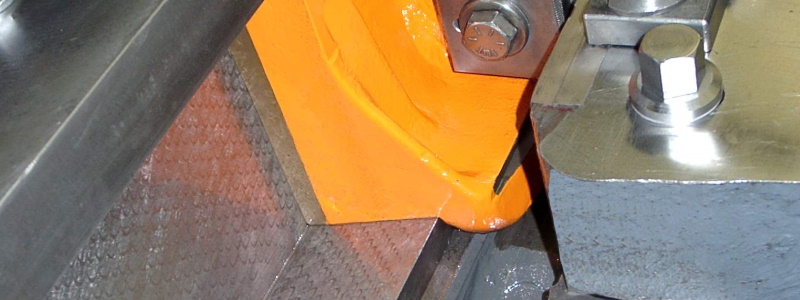

Step 4: Rebuild process begins. We begin rebuilding or remanufacturing the machine, as per the customer’s specifiations. If desired, we can provide progress reports on a weekly or monthly basis.

This is a time-lapse of the assembly process for a customers 3/16" Waterbury Hi-Pro.

-

Step 5: Machine break-in. After completion, the machine goes through the break-in procedure. We cycle the machine on and off, testing each assembly with a gradually increasing run time. Eventually, the machine will be run for up to 12 hours straight. This is to ensure that there are no hot spots, and that the machine will be ready to go into production.

-

Step 6: Customer setup and machine runoff. Before the machine is shipped, the customer is invited to bring setup tooling, wire, any other materials and equipment, and an operator to test the machine at our facility. This allows both the customer and the operator to be confident that the machine will be productive as soon as it hits the factory floor.

Our approach to the rebuilding process is unique in our industry, but we believe it is the best way to approach such a complicated subject. To inquire about machine repair/rebuilding, contact our remanufacturing team via email or phone.